by Admin | Dec 11, 2024

Keeping Your Drain Cleaner in Optimal Condition

As a professional plumber, your drain cleaning machine is more than just a tool

An essential part of your daily operations, the performance directly impacts your ability to deliver a reliable, efficient service to your clients. It is crucial that you routinely maintain your rooter cleaning machine.

Neglecting maintenance shortens the lifespan of the equipment and can lead to costly downtime when you need it most. This detailed guide is for professionals who demand the highest performance from their tools, helping their drain cleaners remain in top condition.

Effective maintenance starts with preparation. Familiarize yourself with your specific model's operational and servicing guidelines by thoroughly reading the manufacturer's manual. Our manuals have detailed diagrams with exact part numbers that can help you navigate the ins and outs of your Gorlitz machine.

While most Gorlitz drain cleaners share similar components, subtle differences can affect maintenance procedures.

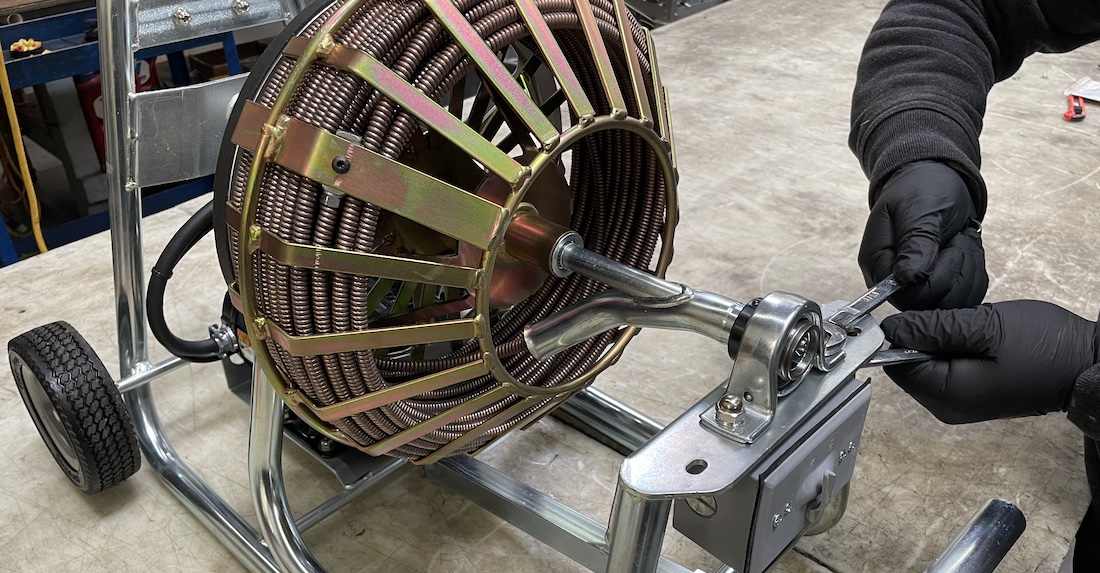

Gather your toolkit: screwdrivers, wrenches, lubricants, cleaning brushes, and replacement parts such as cables, bearings, or seals. For electric models, ensure the machine is powered down and unplugged before you begin.

Personal safety is paramount. Wear gloves, safety glasses, and other protective gear, especially if handling debris or chemical residues. It is good practice to remove the snake coil before performing maintenance to have better access to the rest of the machine.

Visual Inspections: Diagnosing Wear and Tear

As a seasoned professional, you understand that early wear detection is key to avoiding major breakdowns. Below are some general guidelines to help you navigate the visual inspection of your drain cleaning machine.

- Inspecting the cable or snake for kinks or corrosion, paying close attention to any weakened sections. A damaged cable not only reduces performance but can also pose safety risks during operation. Having extras of your most used cables is a wise investment in your operation.

- Examine the motor housing for cracks, dirt accumulation, or compromised seals.

- Ensure the power cord is intact and free from frays or exposed wires.

- Check secondary components like foot pedals and control handles for structural integrity and responsiveness.

As a seasoned professional, you understand that early wear detection is key to avoiding major breakdowns. Below are some general guidelines to help you navigate the visual inspection of your drain cleaning machine.

Cleaning: Maintaining Peak Performance

Keeping your drain cleaner free of debris is critical for professional-grade performance. Begin with the cable or snake, meticulously removing accumulated debris, grease, and buildup. Clean your cable often and allow it to dry before storing it when not in use.

The motor housing or casing should be cleaned using compressed air or a microfiber cloth to prevent dust and dirt from infiltrating critical internal parts.

Detach blade attachments or cutting heads and clean them with a wire brush to maintain precision cutting during operation. Soak them in a cleaning solution, then rinse and dry them to avoid corrosion or other damage to the blades. Regular cleaning not only extends the life of these components but also prevents clogs that can impact the tool's efficiency.

Lubrication: Reducing Wear on Moving Parts

For professional plumbers, keeping moving parts functional is essential. Apply a high-grade lubricant or oil specifically designed for drain cleaner cables. This helps prevent corrosion, reduces friction, and extends the lifespan of the snake.

Consult the manual to identify lubrication points such as bearings, pulleys, or motor components. Apply lubricant sparingly and precisely, as over-lubrication can attract debris and lead to buildup.

Regular lubrication minimizes wear on high-stress components and supports smooth operation under demanding conditions.

Electrical Component Maintenance

Drain cleaners require a rigorous check of all electrical components to guarantee safety and reliability. Inspect the power cord for any signs of wear or damage that could lead to electrical shorts or failures.

Test GFI's, forward/reverse switches, on/off switches, and foot pedals to confirm responsiveness and proper functionality.

After completing the visual and manual inspections, plug the machine into a GFCI-protected outlet and test the motor. Listen for unusual noises, such as grinding or irregular humming, which could indicate issues with bearings or motor alignment.

Monitor for overheating, as this may signal deeper electrical or mechanical problems.

Replacing Worn Parts: Prolonging Machine Life

Even the best-maintained equipment experiences wear over time. Professional grade drain cleaners are no exception, and timely replacement of parts is essential to avoid interruptions in service.

Inspect the snake or cable carefully; if it exhibits significant damage or reduced flexibility, replace it immediately with a Gorlitz high-quality replacement suited for your model.

Other components, such as O-rings, seals, and bearings, should be checked for signs of cracking, wear, or failure. Address any leaks promptly by replacing seals to maintain the machine's integrity.

If pulleys, belts, or other motor components show signs of degradation, prioritize their replacement to avoid costly secondary damage.

Your maintenance manual will have detailed schematics of all the components of your drain-cleaning machine. Please keep it so you can refer to it later should you need to replace any parts that have worn down over time.

Reassembly and Field Testing

After completing all maintenance tasks, reassemble the machine carefully, following the manufacturer's guidelines to ensure every component is correctly aligned and secured.

Conduct a thorough functionality test by running the drain cleaning machine in a controlled environment.

Evaluate the cable's movement, the motor's responsiveness, and the overall performance of the machine. Check for leaks or vibrations that may indicate improper reassembly or lingering issues. Testing under controlled conditions allows you to identify and resolve any remaining problems before deploying the tool in the field.

Professionals

Follow the guidelines of proper storage to prolong equipment life. Store your drain cleaner in a dry, climate-controlled environment to prevent rust and corrosion.

Coil the cable neatly to avoid tangling or damage. Also, consider using protective covers for the machine to shield it from dust and debris.

Polyethylene Drum: If your machine has one, periodically clean it out to prevent uneven wear of expensive parts.

Maintenance Records: A Professional Practice

Maintaining a detailed service log is a hallmark of professionalism. Document the date and details of each maintenance session, noting any parts replaced or issues addressed. This record helps track the machine's performance and provides valuable data for warranty claims or troubleshooting recurring problems.

Set a schedule for regular maintenance based on usage frequency and operating conditions. Quarterly or bi-annual checks are recommended for most drain cleaners, but high-use machines may require monthly inspections.If you have several machines, ensure they are appropriately maintained and rotated amongst the team.

Maintaining a drain cleaner is not a task to take lightly. With regular inspections, cleaning, lubrication, and timely part replacements, your machine will remain a reliable workhorse, ready to tackle even the toughest clogs.

By adopting these advanced maintenance practices, you ensure your equipment is always at peak performance, allowing you to deliver exceptional service to your clients while minimizing downtime and repair costs.

If you need intensive repairs or diagnostics, please bring your machine to us or any authorized Gorlitz distributor for full service and maintenance.

Archives

by Admin | Dec 13, 2024 Essential PPE to Keep on Hand for Every Job The right tools and supplies are essential to ensure you can tackle challenges efficiently...

by Admin | Dec 12, 2024 Essential Tools for Cable Maintenance When performing routine maintenance or unexpected challenges in the field, having the right tools and parts on hand...

by Admin | Dec 11, 2024 Advanced Maintenance Tips for Professional Plumbers Your drain cleaning machine is more than just a tool; it’s an essential part of your daily operations...